According to the different processing methods of the parison, the extrusion blow molding machine is divided into extrusion blow molding machine and injection molding machine. The common is the extrusion blow molding, which is a combination of extruder and blow molding machine and clamping unit, which consists of extruder and die head, blow unit, clamping unit, wall thickness control system and transmission mechanism. Thermoplastic (raw material) is heated to melt by screw rotation, then extruded by die head and cooled.

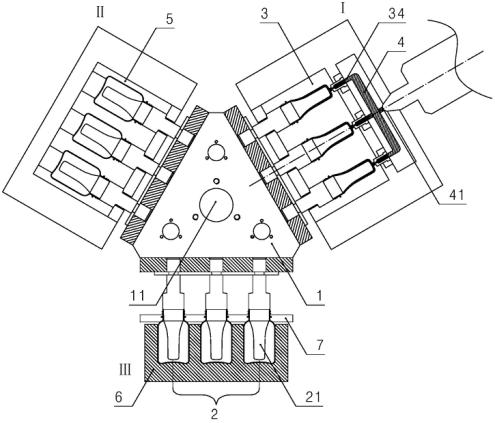

Injection molding machine is a combination of injection molding machine and extrusion blow molding machine, including plasticizing system, hydraulic system, electric system and other mechanical parts. The common types are three station injection extrusion blow molding machine and four station injection extrusion blow molding machine. Injection molding is to put powder material in the hopper of the injection machine, heat the raw material into the molten flow state, push it through the screw or piston, and inject it into the mold cavity through the nozzle, and harden and shape.

There are also large and small classification of extrusion blow molding machines. Small extrusion blow molding machine produces about a few ml to a few liters of product volume. It usually adopts continuous die heads, such as small plastic bottles, cosmetics packaging, toys, oil bottles, detergent bottles, etc. The production volume of large extrusion blow molding machine is several hundred liters to tens of thousands of liters, and the die head of the storage cylinder type is generally adopted. The products produced are widely used, such as roadblocks, industrial water tanks, large plastic buckets, industrial facilities, etc. seen on the roadside.

Choose which type of extrusion blow molding machine depends on their own product production needs. Including the application field, use place, performance requirements of products, etc., are all the factors that we consider in choosing the extrusion blow molding machine equipment.